Corrosion and Pitting

The Problem:

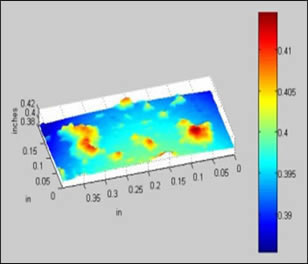

3D Image of Gun Tube Corrosion

3D Image of Gun Tube CorrosionThe Solution:

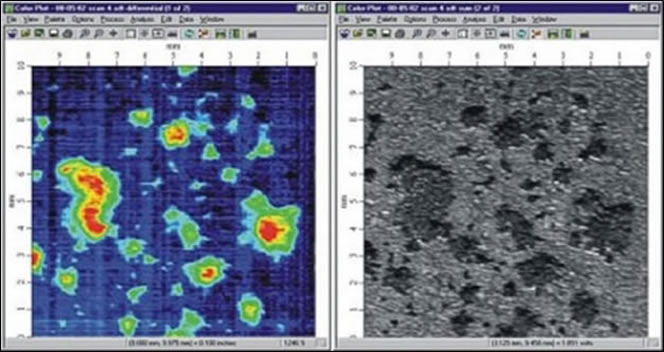

LTC's Laser MicroMap™ system is ideal for inspecting parts subject to corrosion and pitting to determine their condition. Our laser surface mapping sensors can provide a 3D map of the part surface, allowing precise measurement of the amount of remaining material. In particular, our Laser MicroMap™ Tube Inspection system is ideal for internal corrosion monitoring of tubes and pipes. Our LaserViewer™software contains tools for statistical analysis of all or part of a scan, and the file comparison feature enables quantitative comparison between parts or over time. In addition, the LaserVideo™ image generated by the laser mapping sensor provides important qualitative information about surface features that cannot be measured by laser profiling, such as discoloration and surface roughness.

Dimensional (left) and LaserVideo™ (right) Images of Corrosion in a Chrome-Plated Gun Tube